2013

How It All Began: A Maker's Early Spark

#The Wounds

“I'm obsessed with making my own stuff since my early days.”

2013

How It All Began: A Maker's Early Spark

#The Wounds

“I'm obsessed with making my own stuff since my early days.”

#The Class

“The future was already happening — I just happened to step into it.”

#The Class

“The future was already happening — I just happened to step into it.”

#The Team

“We realized that kids are natural inventors, but lack safe, capable tools.”

2013-2016

From Creativity to CardBoard

2013-2016

From Creativity to CardBoard

#The Team

“We realized that kids are natural inventors, but lack safe, capable tools.”

2016-2019

Drill + Nibbler = Kids Table Saw?

#The First Blueprint

“Spilt the cutter into parts.”

2016-2019

Drill + Nibbler = Kids Table Saw?

#The First Blueprint

“Spilt the cutter into parts.”

#The Second Blueprint

“Transform a nibbler into a table.”

#The Second Blueprint

“Spilt the cutter into parts.”

2019–2021

From Original Design to Real-World Prototypes

2019–2021

From Original Design to Real-World Prototypes

2022–2023

A Companion, Not Just a Tool

2022–2023

A Companion, Not Just a Tool

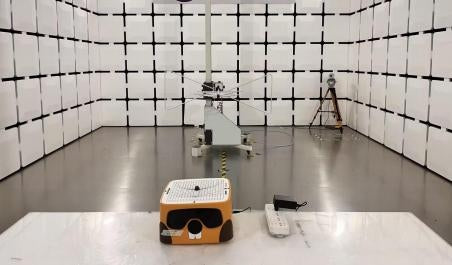

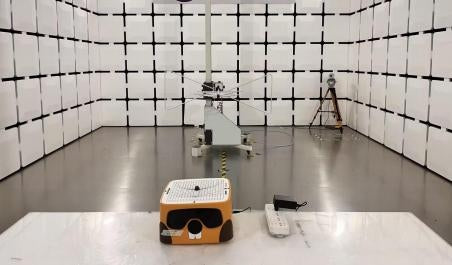

2024

Rigor, Reliability, and Ready for the World

12000+

1030+

5

2024

Rigor, Reliability, and Ready for the World

12000+

1030+

5

2025

From a Workshop Dream to a Worldwide Mission

2025

From a Workshop Dream to a Worldwide Mission

2026 and Beyond

2026 and Beyond